Single Bed Reactor

16ized bed reactors is in the initial stage of the laboratory scale and its feasibility is not yet established. The simple two-phase model was found to underpredict the performance of the fluidized-bed reactors because of the oversimplified assumptions involved in this model.

Visual Encyclopedia Of Chemical Engineering

Search for more papers by this author.

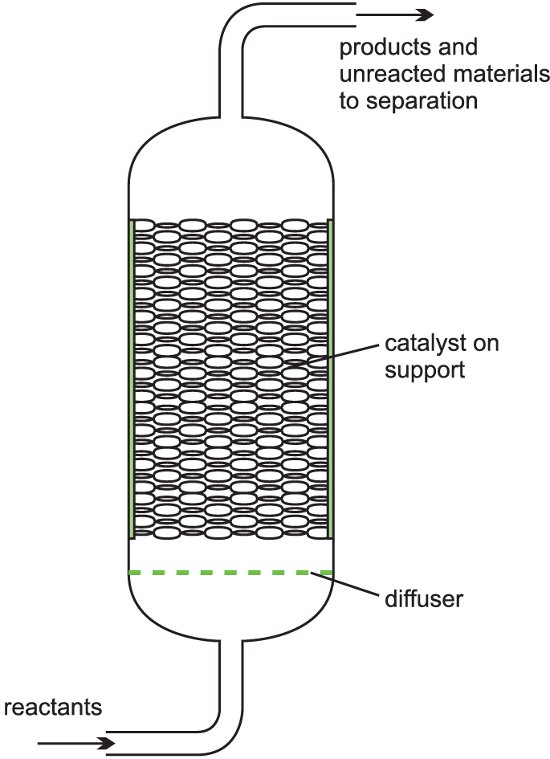

Single bed reactor. 15How a Packed Bed Reactor Works. A a simple two-phase flow model b a dynamic two-phase structure model and c a plug-flow model. Single Bed Sebagai penyangga katalisator dipakai butir-butir alumunia bersifat inert terhadap zat pereaksi dan pada dasar reaktor disusun dari butir yang besar makin keatas makin kecil tetapi pada bagian atas katalisator disusun dari butir kecil makin keatas makin besar.

Ray University of Waterloo Ontario Canada. The hydrodynamics of trickling flow in packed beds operating at high pressures. In single-phase packed bed systems the fluid can be either a gas or liquid.

26The performance of the reactor was investigated using three different models. Empty and clean reactor t c Varies 05-10 Total cycle time excluding reactionTotal cycle time excluding reaction 3030-6060 Batch polymerization reaction times may vary between 5 and 60 hours. Heat to reaction temperature t e 15-30 02-20 3.

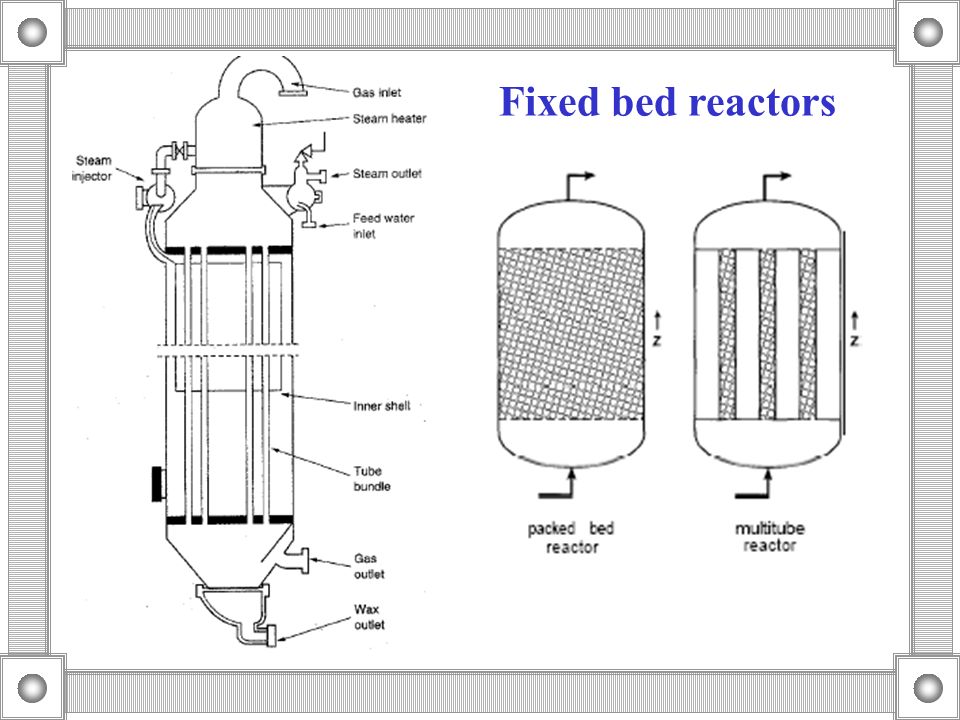

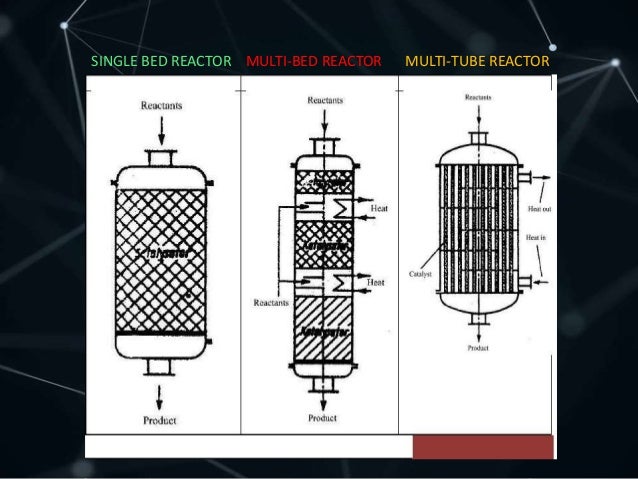

The common reactors used for solid waste gasification include fixed bed fluidized bed and entrained flow reactors. In such cases several fixed bed reactors are connected in series. Packed bed reactors are very versatile and are used in many chemical processing applications such as absorption distillation stripping separation processes and catalytic reactions.

Ogunye University of Waterloo Ontario Canada. They can be built on single or multiple tubes as per requirement. Typical reactors consist of a chamber such as a tube or channel that.

S actoractor fine catalyst particles are suspended in a solvent and feed gas enters. A fixed bed reactor. Investigators are studying two different reactor types for the commercialization of DME synthe-bubblinsi sg slurry reactor and fixed beurry re In al d re.

Across the diverse applications in which they are used the physical dimensions of the beds can vary greatly. Search for more papers by this author. Along the reactor and optimal control.

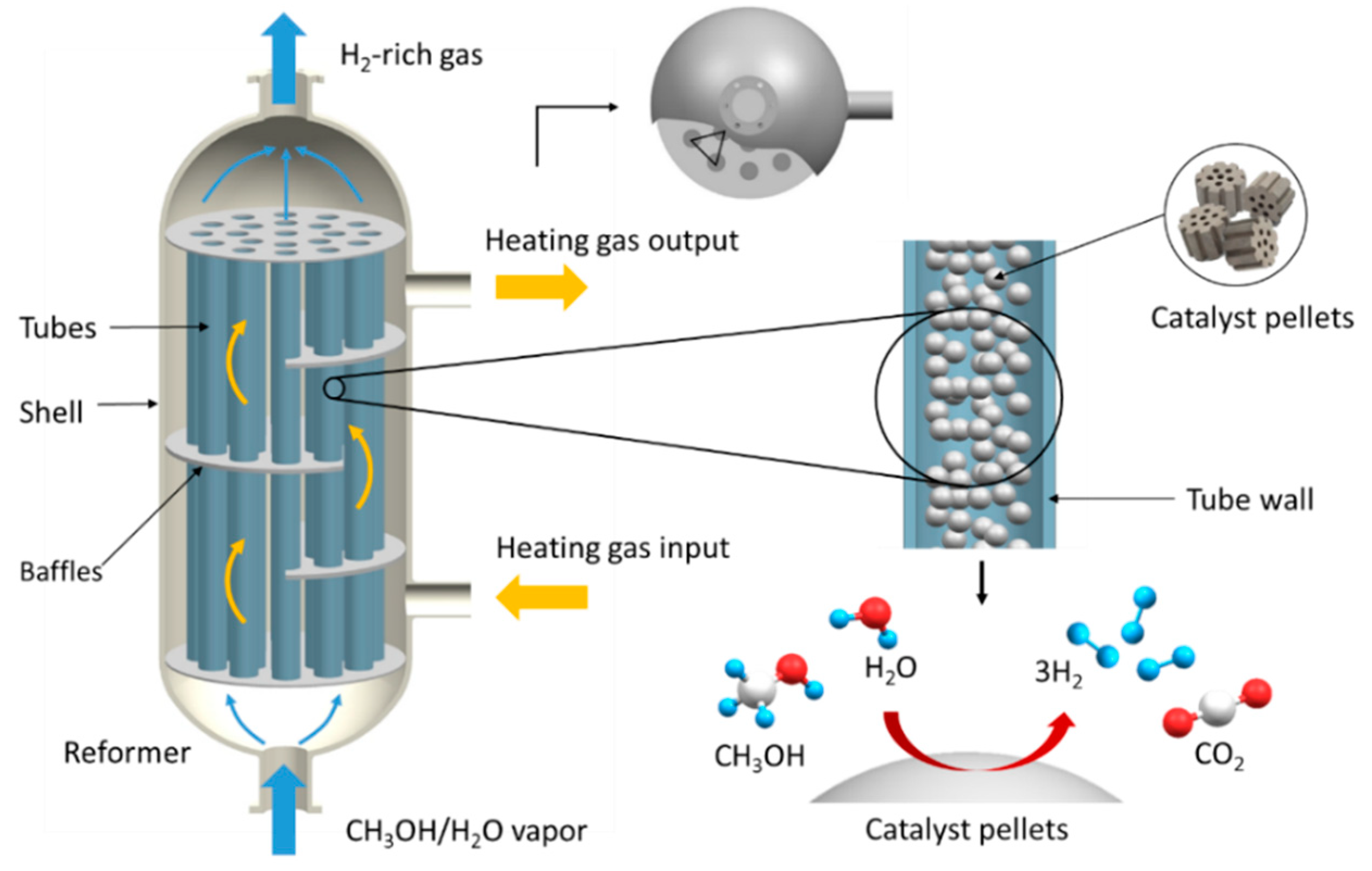

Reactors with a single adiabatic bed are traditionally used in either exothermic or endothermic reactions. A multitube fixed bed reactor and the use of such a reactor for carrying out catalytic gas-phase reactions in particular for carrying out exothermic and endothermic catalytic gas-phase reactions such as the preparation of phthalic anhydride PA acrylic acid methacrylic acid MAA acrolein maleic anhydride MA glyoxal phosgene hydrocyanic acid or vinyl formamide VFA. An ideal packed bed reactor with single-phase flow can be described by the Ergun equation which describes the pressure drop across the bed and how it is related to particle size bed length void space or porosity fluid velocity and viscosity.

For the single bed reactors frequent unit shutdown for catalyst replacement can not be avoided for the feeds containing asphaltenes and heavy metals. 18In conclusion the presented results demonstrate firstly the value of an easy-to-use method to compute optimal temperature profiles in single-stage fixed-bed reactors secondly the high potential of thermal optimization that lies in the Sabatier process and thirdly the need for catalyst supports with enhanced heat transport that allow larger tube diameters for highly exothermic processes. B4 Fixed-Bed Reactors 199 Fixed-Bed Reactors GERHART EIGENBERGER Institut flir Chemische Verfahrenstechnik Universitiit Stuttgart Stuttgart Federal Republic of.

Single bed adiabatic reactors radial flow reactors multiple bed isothermal reactors and non-adiabatic multi-tubular reactors. The two types of reactors in the Fixed Bed category commonly include Packed Beds and Multi-tube reactors. Carry out reaction t Vi R 4.

Flow through packed bed reactors. In this case the first reactor is designed as a guard reactor. In both one-phase and two-phase systems the reactor can be oriented either horizontally or vertically.

1Bentuk reaktor fixed bed dapat dibagi menjadi. 12In single-staged reactor systems different types of reactors have been utilized based on their advantages and disadvantages. Flow through packed bed reactors.

Modeling of laboratory and commercial scale hydro-processing reactors using CFD. 24Types of Packed Bed Reactors There are four major types of packed bed reactors intended for gas phase reactions. 13In order to design such a fixed bed reactor it is necessary to be able to predict the temperature and concentration at every point in the reactor since present design methods are based on the numerical integration of basic differential equations which can be derived from material and energy balances over a differential element of the bed.

Fixed Bed of catalyst used to carry out heterogeneous catalyzed gas-phase reactions. Charge feed to the reactor and agitate t f 2. Detailed numerical examples are worked for isothermal reactors adiabatic reactors.

In two-phase reactors both liquid and gas flow over the solid particles in either co-current or counter-current beds.

Fixed Bed Reactor An Overview Sciencedirect Topics

Schematic Representation Of The H Oil Reactor Download Scientific Diagram

Fluidized Bed Reactor For Polyethylene Production Download Scientific Diagram

Https Link Springer Com Content Pdf 10 1007 2f978 3 540 68622 4 11 Pdf

Different Types Of Reactors And Their Industrial Applications Pharma Grip

Elements Of Chemical Reaction Engineering

Pdf Modeling Of A Catalytic Packed Bed Reactor And Gas Chromatograph Using Comsol Multiphysics Semantic Scholar

Chemical Reactors Ppt Video Online Download

Schematic View Of The Single Tube Fixed Bed Reactor Download Scientific Diagram

Trickle Bed Reactor An Overview Sciencedirect Topics

Energies Free Full Text Modeling And Design Of A Multi Tubular Packed Bed Reactor For Methanol Steam Reforming Over A Cu Zno Al2o3 Catalyst Html

High Purity Fructose From Inulin With Heterogeneous Catalysis From Batch To Continuous Operation Perez Nebreda 2019 Journal Of Chemical Technology Amp Biotechnology Wiley Online Library

Schematic View Of The Single Tube Fixed Bed Reactor Download Scientific Diagram

Https Link Springer Com Content Pdf 10 1007 2f978 3 540 68622 4 11 Pdf

The Structure And Different Parts Of Fixed Bed Reactor Download Scientific Diagram

A Process For The Oxidation Of Propylene To Acrylic Acid And Of Isobutylen To Methacrylic Acid Patent 0010206

Schematic Diagram Of The Packed Bed Reactor Download Scientific Diagram

Trickle Bed Reactor An Overview Sciencedirect Topics

Post a Comment for "Single Bed Reactor"